It started due to adventurous spirit of Ninja ( as known on Baby DiyA ) – he found them somewhere on web adds , I believe in Denmark .

As he said – “I don’t know do I need them , but somebody will “ ; due to fact that one is reported as having de-centred bass cone , they were pretty decent price-wise .

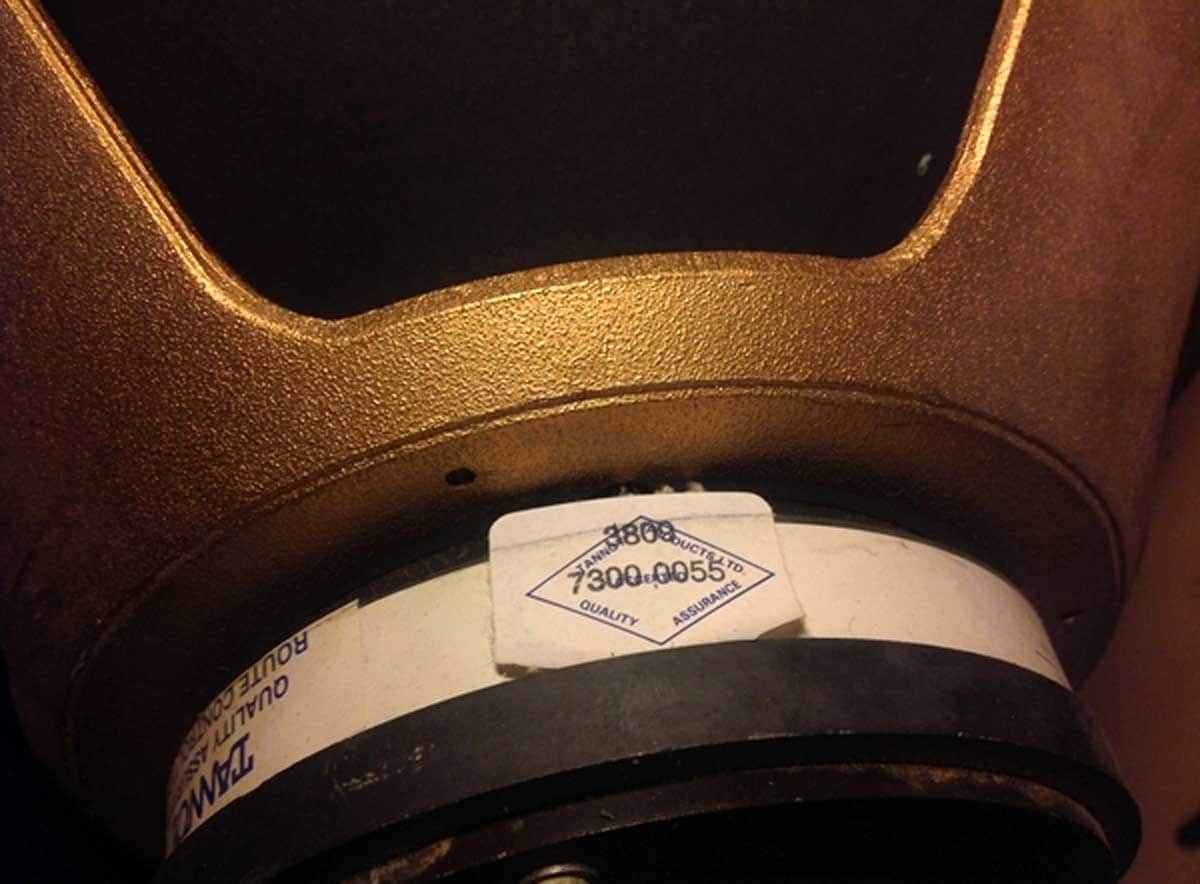

Pretty benign pictures , sent to Ninja from seller ; half-luck – just one is having K3809 type sticker , but both are no-back-ribs …… we were hoping in that moment that no-name one is not K3805 (higher Fs , used in Puma cabs) :

So – after pretty troublesome (read – not so easy communication with seller ) they’re paid for and shipped to another Baby DiyA colleague – Paja959 (in Budapest ; he smuggled them later to next link in chain , in Serbia 😉 ), and you can see how clever they were packed , rubbing rim to rim ….. with exactly nothing in between :

OK , few weeks later , they arrived to my living room ……. first inspection , naturally puzzled what’s that “one bass cone de-centred” issue …… Rdc measurement are saying that both bass coils are in ballpark (5R2 vs. 5R4 ) while Hf coils are somewhat different , but pretty normal for Tannoy Hf ‘fragm’s spread – 7R8 vs. 9R1 ; also – I realized that one dust cap is loose , but everything is looking as from factory , not sloppy amateurish work . However , reported buzzing (de-centering) issues for that driver were most probably nothing more than flapping dust-cap

😉

Next day …… some disassembling ; first I removed both Hf ‘fragms , to inspect them . As I hoped – everything as from Day One . There are some usual factory notes on VC formers and around :

Next , after covering Hf side holes ( both gap and Pepperpot holes) with sticky paper tape , I removed magnets from baskets . Yup , bass-side gaps and horn throats are also covered with same tape.

Now – major surprise !

What I found laying on inner spider side ……… is small basket particle – certainly waste from process of punching/pressing screw-holes ; dia 4mm x 2.5mm :

And , now , whatever that was , issue was from that particle ……. don’t know exactly how , but it resulted in this (luckily not fatal to VC continuity ) …. lower edge of VC former is damaged in two places , exactly up to wire , without damaging wire itself :

Huh …… I pulled former edge slightly back , adding some nitro-paint just to secure it :

While I was there …. I made mass based flex test of spiders on both drivers – I’m breathing easier now – flex test of spiders confirmed identical spiders , which means that both are of K3809 type 😉 .

Surrounds (both drivers) are rock solid , leading to (already expected ) fact that they’re needing same procedure which I already made with my own pair of K3809 .

Just one picture of back side of hardened surround ; good to see that there are no splits or cracks, anywhere on perimeter , on both drivers :

Anticipating need for proper VC centering later , I removed dustcaps ; interesting – then were clearly visible differences between two cones :

– black magnet equipped driver , having K3809 sticker , is having gold paint sprayed horn throat, and full height Al VC former ;

-white magnet equipped driver (not having type sticker ) is having silver horn throat, and 3/4 height natural color Al VC former ……

However , due to fact that my own pair of K3809 is having exactly same (3/4 height Al ) VC formers , I came to conclusion – from all facts – that both drivers in case are K3809 , while differences are irrelevant and normal for Tannoy production .

….. To be continued – cleaning magnets with compressed air , painting both throats to be matched in color , reassembly with VC centering , surround revitalization , two Dammar layers for cones.

Considering previous experience ….. I believe some 35+ hours of work are needed for entire procedure …….. 😉